Though traditionally dominated by metal, the HVAC industry is increasingly turning to the state-of-the-art Fiberglass Reinforced Plastic (FRP) ductwork. FRP’s high-strength characteristics combined with its lightweight nature, cost-efficiency, material integrity, durability, versatility, ease of use, exceptional protection from corrosion, and minimal maintenance requirements allow it to outperform other materials on the market.

Custom Ducts for Your Unique Application

At VPC Fiberglass, we provide a wide range of high-quality custom FRP products that meet your requirements. Engineered for each specific application, our custom ducting can be purposed for unique applications and adjusted for any situation or environment. With air handling customization, our expert team can work to make the fans and the ductwork one system to serve your unique application.

Duct Shapes & Sizes

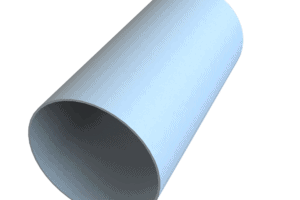

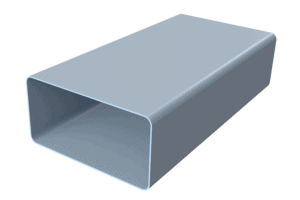

Our fiberglass HVAC ductwork comes in different shapes and sizes:

- Round Duct: From 2-inch to 96-inch

- Rectangular Duct: Up to 36 x 36 inches (bigger sizes are available for custom orders)

Duct Fittings

VPC Fiberglass offers a complete line of fiberglass fittings which include:

- Elbows

- Tees

- Crosses

- Laterals

- Y branches

- Reducers – Concentric Reducer and Eccentric Reducer

- Dampers – Round Damper and Square Damper

- Stacks

The Benefits of Fiberglass Ductwork

Fiberglass ductwork offers numerous benefits over traditional ductwork materials:

- Shape and sizing: Fiberglass ductwork can easily be molded into different shapes and sizes to meet your exact specifications.

- Corrosion resistance: Fiberglass ductwork has excellent corrosion resistance, and the corrosion barrier can be customized per your requirements.

- Strength under high air pressure: FRP ducts possess enhanced strength properties. It also has high tensile strength, flexure strength, and impact strength.

Applications & Industries Served

FRP ductwork can also be used in these industries:

- Air Handling/Heating, Ventilation, & Air Conditioning (HVAC): FRP ducting can be used in a wide variety of HVAC applications. This versatile material is compatible with industrial ventilation applications, corrosive environments, and underground and exhaust ductwork systems.

- Beverage & Pharmaceutical: Our corrosion-resistant FRP ducts are the ideal solution for the harsh products and wet environments found in the beverage and pharmaceutical industries.

- Chemical: Fiberglass ducting is used in chemical facilities to provide a corrosion-resistant solution for airflow.

- Industrial: FRP ducting can be used in numerous industrial applications since it can withstand exposure to corrosive and provide excellent durability materials.

- Highly Corrosive Environments: Fiberglass ducts are specifically designed to withstand highly corrosive environments and are a clear choice over other types of ductwork, such as galvanized, stainless steel, PVC coated galvanized, or PVC.

- Food: Food processing requires hygienic air handling as a critical element of the food processing environment to ensure safe consumption for consumers.

- Pulp & Paper: FRP ducts are used in pulp and paper facilities due to their ability to withstand the corrosive chemicals used in paper processing operations.

- Water & Wastewater: Fiberglass duct contains the flow of corrosive air through the activated carbon reactors, fans, and scrubbers.

- Government (DoD): Fiberglass ducts can also be manufactured to meet government and military specifications.

- Laboratory Exhaust: Condensate formed in the duct system can concentrate these chemicals due to evaporation, making them even more corrosive.

Contact Our Experts for Your Custom Ductwork Needs!

At VPC Fiberglass, we have years of experience manufacturing high-quality custom ductwork for different applications across various industries. Our fabricators work closely with your engineers to develop HVAC ductwork that meets your specifications and will ensure nonconformity at all stages of the manufacturing process, from design to fabrication and service during and after HVAC ducting installation. Contact us to request a quote about our custom ductwork services.