Packaged manhole systems are integrated systems crucial to sewage, water collection, utility, electrical, and communication applications. Manholes can be made from fiberglass or composite materials, and packaged manhole systems include a manhole reducer, manhole barrel, ladder, ladder assist, base mounting flange, and other components upstream or downstream of the manhole barrel. An effective packaged manhole system is quick to install and lasts a long time.

Composite manhole covers are constructed from fiber-reinforced polymers (FRP) or fiberglass. Manhole covers made from fiberglass are an affordable option to control or measure piped flows. They are lightweight, corrosion-resistant, durable, cost-effective, and easy to install.

Learn more about the essential elements of packaged manhole systems and how to identify the various components.

Composite Manhole Stack

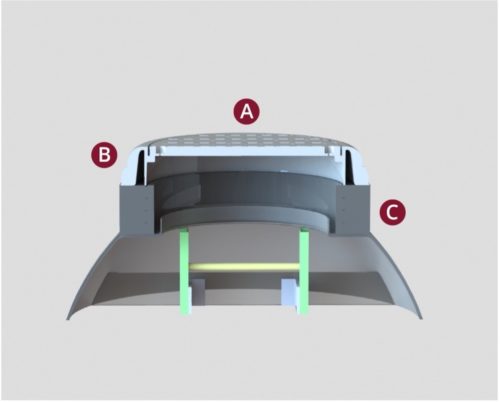

Stack elements are only required for composite manholes rated for H-20 loading—a type of composite manhole specially designed for installation in areas with high vehicular traffic. They are not used on aluminum pedestrian hatches or fiberglass domed top manholes. The installing contractor usually supplies the stack, or it is sold as part of a complete packaged manhole system. The stack elements include:

A. Manhole Cover: Also called a biscuit, a manhole cover is a removable composite (FRP) plate that covers the opening of a manhole to keep out unauthorized personnel and prevent people or debris from falling in. Manhole covers also come in cast iron, aluminum, or steel materials. Composite manhole covers are corrosion-resistant and cost-effective while offering long-term protection.

B. Manhole Cover Frame: The manhole cover frame can also be made from FRP, steel, aluminum, or cast iron. It allows the cover to form a watertight seal.

C. Grade/Adjustment Ring: This stack section is made from concrete and functions to bring the manhole cover to grade.

Manhole Package

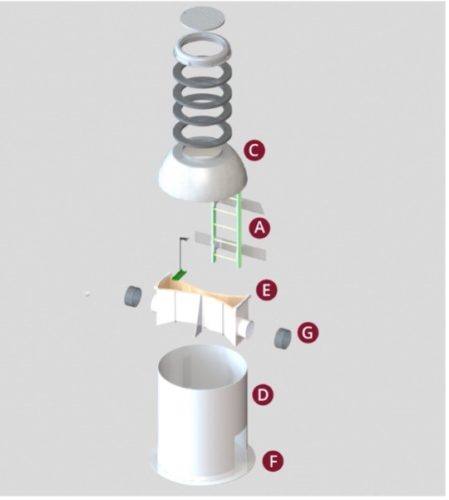

A complete metering manhole package includes:

A. Ladder and Ladder Assist: The fiberglass ladder is reinforced with stainless steel and specially designed for use in manholes. It comes with non-slip treads for improved safety and meets or exceeds the safety standards set by OSHA. The ladder assist is an optional component in a manhole package. It is a stainless steel extension pole that offers easier access in and out of the manhole.

B. Confined Space Entry Sign (not pictured): This OSHA-compliant sign informs the public that the area is restricted and reminds workers of the potential hazards of working in confined spaces.

C. Manhole Reducer with Shoulder: Usually with a shoulder, the manhole reducer transitions the load from the stack elements to the manhole barrel walls.

D. Manhole Barrel: This is the part of a manhole that acts as the body of the underground space. A manhole barrel is designed to meet the Standard Specification for Glass-Fiber-Reinforced Polyester Manholes and Wetwells (ASTM D3753).

E. Flow Elements / Meter: (flume, weir, ultrasonic mounting bracket, mag meter), grinder channel, energy absorber, stormwater screen, or diversion channel.

F. Closed Base: The closed base features a fully watertight construction that prevents the entry of groundwater.

G. End Connection: Pipe stubs, flanges, or caulking collars to direct flow in and out of the manhole.

Packaged Manhole Systems From Virtual Polymer Compounds

Virtual Polymer Compounds produces high-quality packaged manhole systems with the highest quality fiberglass materials. We have state-of-the-art technology to provide you with ideal solutions for nearly any environmental condition. Our experienced team of engineers is always on standby to guide you through the whole process, from manhole system design to manufacture to installation.

If you have any questions about our products and services, don’t hesitate to contact our support team. To get started on your next project, feel free to request a quote today.

Comments are closed